+1 915 229 3004 (U.S.) |

+1 915 229 3004 (U.S.) |  +44 7452 242832 (U.K.)

+44 7452 242832 (U.K.)

+1 915 229 3004 (U.S.) |

+1 915 229 3004 (U.S.) |  +44 7452 242832 (U.K.)

+44 7452 242832 (U.K.)

According to Research Layer, The global 3D Metal Printing market size was valued at USD 4.1 billion in 2021 and is expected to reach to 28.3 billion at a compound annual growth rate (CAGR) of 24.3% from 2022 to 2030.

A major market-expanding factor is the rising use of metal 3D printers for designing and prototyping goods, which is facilitated by lower manufacturing costs and improved product accuracy. High demand is anticipated in the market, especially from the healthcare, automotive, aerospace, and military industries. The healthcare industry is developing rapidly and adopting new cutting-edge techniques, like 3D printing, to combat physical disabilities and promote healthy living. Additionally, the automotive and aerospace industries, where prototyping and designing are crucial to research and development to achieve perfection in their production, are paving the way for more opportunities and accelerating the adoption of the 3D printing technique.

However, the widespread misunderstandings of the prototype techniques being held back the adoption of additive manufacturing by small and medium-sized businesses. Design-focused firms, especially SMBs, are hesitating to invest in prototyping because they don't fully understand the benefits it may bring. Prototyping is seen as an unnecessary and costly extra step before mass production by these companies. Misconceptions like these regarding prototyping, along with a shortage of technical knowledge and the imminent absence of standardised process controls, are expected to slow the global 3D Metal Printing market.

Download Free Report Sample to learn more about this report.

The COVID-19 pandemic outbreak has had a major effect on the global economy as a whole and, consequently, the 3D printing sector. In the beginning, Europe and Asia-Pacific were among the areas with the greatest number of COVID-19 patients worldwide. Additionally, things became worse over in the United States. The governments issued an order for the total lockdown of some important cities due to the virus' quick spread. The whole lockout has an impact on 3D printing industry production. The nation's logistics and supply chain have been completely disrupted, which is blamed for this along with the labour deficit. The suspension of 3D printing production had a negative effect on the market's overall growth in the first and second quarters of 2020.

3D Printing Metals Market Driver

Applications such as A&D are Driving the Market Growth for 3D Printing Metals

The popularity of 3D printing metals could usher in a new era for the metal processing sector. These items are appealing because of their complicated geometries and physicochemical characteristics. The demand for complex, high-precision parts in the aerospace and defence industries has been a major factor in the market growth for 3D printed metals. Three factors influence the use of 3D printed metals in sectors like the automotive, medicinal, and dental industries. A rise in the demand for implants and prosthetics will be seen, as well as increased investment in new products, new materials, and metals for prototyping. It is anticipated that significant developments will be made in the field of aircraft manufacturing using 3D printing during the forecast period. The rising acceptance of 3D metal printing, which offers benefits such as greater design stability, reduced waste, and more affordable pricing when compared to traditional manufacturing techniques, may be a significant metal 3D printing market driver.

3D Printing Metals Market Opportunity

The Increasing Exploitation of Untapped Market Channels

In recent years, advances in 3D printing technology have made it possible to print metals for use in a variety of scientific fields. Technological advancements that lower the price of high-quality 3D printers could be a game-changer for the industry in the coming years.

3D Printing Metals Market Restraint

High Technology Costs

For this reason, it has been incredibly difficult to bring 3D printed metals to market because of the vested interests of the end-use industries. Production companies may be reluctant to invest in the technology because of its high price tag. 3D printing has its limits even when making very massive objects. In comparison to 3D printing, its use in mass production is now highly unlikely.

The market for metals used in 3D printing is still growing significantly in the field of space exploration. The Stargate metal additive manufacturing platform from Relativity Space has just been updated. Stargate 4th Generation metal 3D printers will be used to manufacture the majority of the Terran R launch vehicle. The Terran R rocket, which can carry 20,000 kg into low-Earth orbit, is entirely reusable. Stargate printers' quick iteration cycles are designed to open up new avenues for innovation in mass-produced goods. What can be created and built by conventional aerospace and space manufacturers in months can instead be done in years thanks to a highly flexible, scalable, and automated process made possible by software-driven manufacturing.

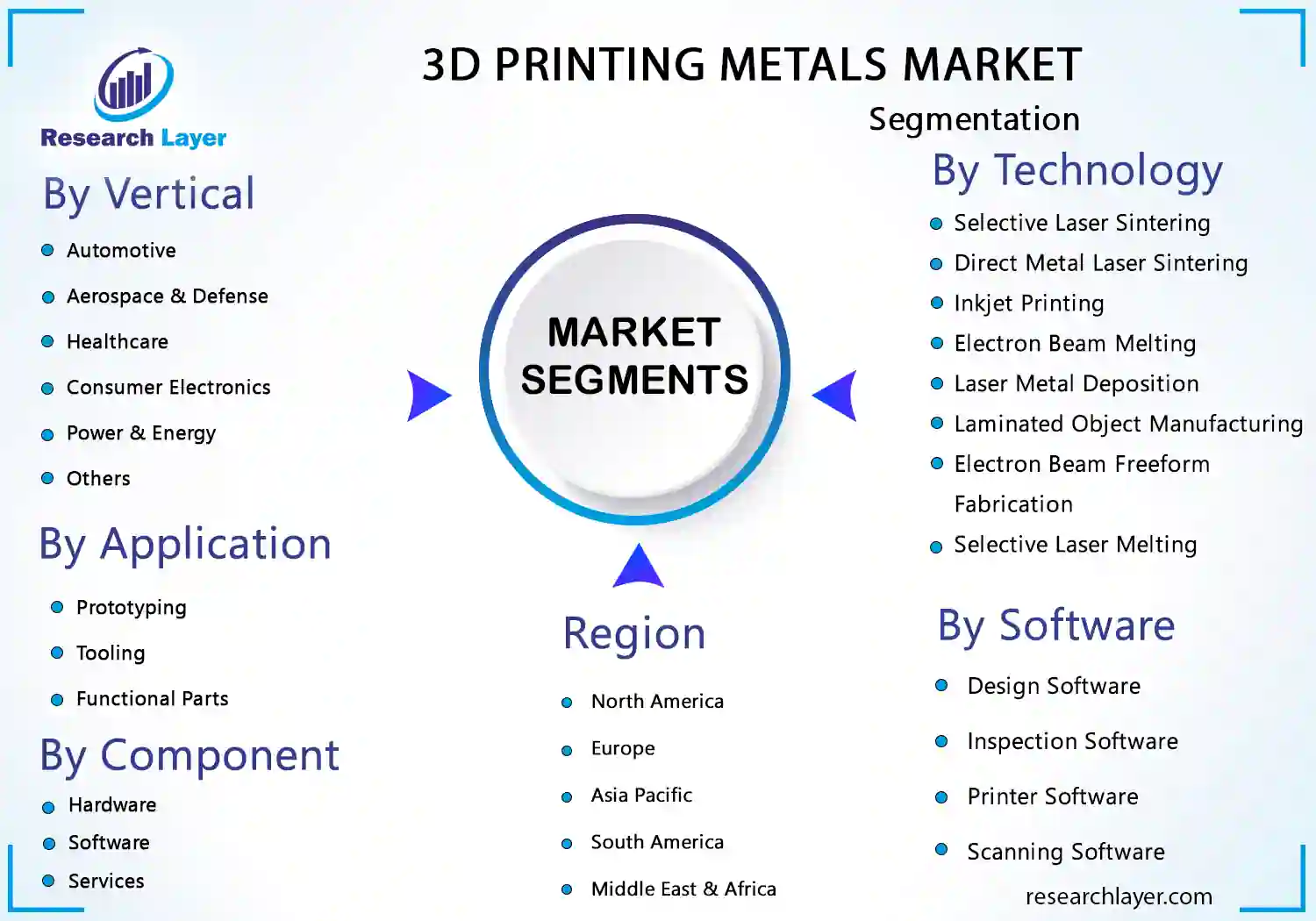

The global 3D Printing Metals Market has been segmented based on component, technology, software, application, vertical, and region/country.

Selective Laser Melting (SLM) technology led the market and accounted for more than 18.0% share of the global revenue in 2021. Although the benefits and simplicity of the SLM technology's operations are encouraging its adoption, technological advancements and aggressive research and development efforts made by experts in the field and researchers are creating opportunities for a number of other effective and dependable technologies. Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), Inkjet printing, Electron Beam Melting (EBM), Laser Metal Deposition (LMD), Laminated Object Manufacturing (LOM), and Electron-beam Freeform Fabrication are additional 3D metal printing technologies.

Design software led the market and accounted for more than 37.0% share of the global revenue in 2021. Particularly in the automotive, aerospace and defense, construction and engineering verticals, design software is used to create the designs of the object to be printed. Design software serves as a conduit between the hardware of the printer and the objects that will be printed.

The prototyping segment led the market and accounted for more than 52.0% share of the global revenue in 2021 due to the extensive adoption of the prototyping process across several industry verticals. Prototyping is used extensively in the automotive, aerospace, and defence industries to precisely design and develop parts, components, and complex systems. Manufacturers can develop trustworthy final products and achieve higher accuracy through prototyping. Consequently, it is anticipated that the prototyping segment will continue to rule the market over the period of the forecast.

Download Free Report Sample to learn more about this report.

The global 3D Printing Metals Market has been analyzed for five regions—North America, Europe, Asia-Pacific, the Middle East & Africa, and South America.

The geographic analysis of the global 3D Printing Metals Market has been conducted for North America, Europe, Asia-Pacific, the Middle East & Africa, and South America.

North America dominated the market and accounted for over 33.0% share of the global revenue in 2021 owing to the extensive adoption of additive manufacturing in the region. The U.S. and Canada are two examples of North American nations that were among the leading and early adopters of these technologies in a variety of manufacturing processes. For various applications, the regional market provides 3D metal printing with lucrative opportunities. Given its size in terms of geography, Europe is the largest continent. It is home to a number of industry participants in additive manufacturing who have extensive technical knowledge of the processes. As a result, the European metal 3D printing market is the second-largest.

Over the forecast period, Asia Pacific is anticipated to experience the highest CAGR growth. This quick uptake of 3D metal printing in Asia Pacific can be attributed to improvements made throughout the region's manufacturing sector. Additionally developing as a manufacturing hub for the healthcare and automotive sectors is the Asia Pacific region. Rapid urbanisation and a stronghold on consumer electronics manufacturing are other factors boosting three-dimensional printing demand in the area.

Download Free Report Sample to learn more about this report.

· Austrian engineering company Incus announced a partnership with the European Space Agency (ESA), OHB System AG, and Lithoz GmbH in October 2021 to create and test microgravity 3D printing for approved space parts. Incus Lithography-based Metal Manufacturing (LMM) creates components with superior surface aesthetics and materials that are comparable to those used in metal injection moulding on Earth (MIM).

· The Amcell 8300 and Amcell 1400 are two new models that Triditive, a producer of industrial 3D printers, added to its Amcell 3D printer range in October 2021. The new machines are made to enable both mass production of industrial 3D printed parts and large-scale manufacturing of parts in a variety of materials. They can print both metal and polymers interchangeably. The newest generation of 3D printers from Triditive, according to CEO Mariel Daz, can print metal and polymer parts as well as complex components, which can reduce part time to market.

· A leading aerospace manufacturer, Honeywell, revealed in October 2020 that it had tested the high-temperature alloy ABD 900AM, a new additive manufacturing (AM) material from Alloyed, for use in 3D metal printing for the aerospace industry.

· A new software update for Digital Metal's DM P2500 3D printer was released in April 2020. This Swedish company produces binder jetting metal 3D printers. The modification tripled the DM P2500's print speed by enabling a significantly higher production volume per time unit.

· In the UK, Materials Solutions has a new 3D printing plant that Siemens has opened. A $27 million investment has been made in the factory that will help 3D printing become more industrialised.

The key players in the global 3D Printing Metals Market are Materialise NV, 3D Systems Inc, GE Additive, Autodesk Inc, Optomec Inc.

This study estimates revenue growth at global, regional, and country levels and offers an overview of the latest developments in each of the sub-sectors from 2022 to 2030. For this analysis, Research Layer segmented the global 3D Printing Metals Market has been segmented based on component, technology, software, application, vertical, and region/country.

· Potential Investors

· Regulatory & Government Bodies

· Research & Consulting Firms

· Upstream & Downstream Vendors

· End Users

· Others

Report Scope

The global 3D Metal Printing market size was estimated at USD 4.1 billion in 2021

The global 3D Metal Printing market is expected to grow at a compound annual growth rate of 24.3% from 2022 to 2030

North America dominated the 3D Metal Printing market

Some key players operating in the 3D Metal Printing market include Materialise NV, 3D Systems, Inc., GE Additive, Autodesk Inc., Optomec, Inc.

Key factors that are driving the 3D Metal Printing market growth include increasing adoption of metal 3D printers for designing and prototyping of products & objects coupled with the reduced manufacturing expenditure and accuracy in the end-product.

Report Code :

RL6532

Published on :

Dec 2022

Request a Free Sample Report